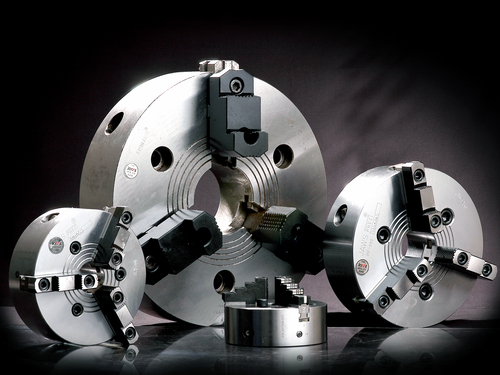

Quick Jaw Change Power Chucks

Price 550-250000 INR/ Piece

Quick Jaw Change Power Chucks Specification

- Product Type

- Quick Jaw Change Power Chuck

- General Use

- CNC Lathe Machines, Turning Centers, Milling Machines

- Material

- Alloy Steel Body

- Type

- Power Operated

- Capacity

- Varies by Model (typically up to 8000 RPM clamping capacity)

- Computerized

- No

- Automatic

- Yes

- No. Of Jaws

- 3

- Power Source

- Hydraulic / Pneumatic

- Dimension (L*W*H)

- Varies by Model (e.g., 210x210x110 mm, 250x250x125 mm)

- Feature

- Quick Jaw Change, High Clamping Force, High Speed, Accurate Positioning

- Color

- Silver/Grey

Quick Jaw Change Power Chucks Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

About Quick Jaw Change Power Chucks

To meet our clients requirements, we are able to manufacture, supply and export premium grade Quick Jaw Change Power Chucks. Our clients can avail these chucks in many sizes and specifications as per their requirements. We manufacture the chuck components by making use of best-in-class alloy and carbon steel, to ensure longer service life, corrosion-resistant nature and sturdy construction. These Quick Jaw Change Power Chucks are offered to our customers only after thorough examine and conformation from our high-ranking officials.

Other details:

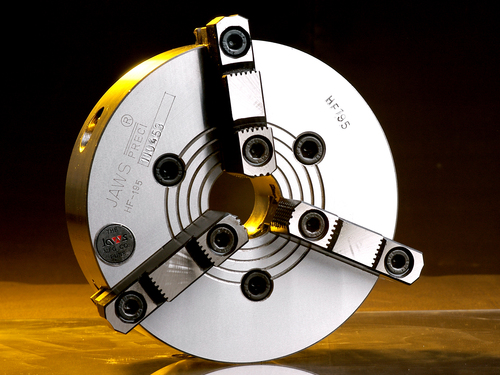

PRECI chucks earlier manufactured by Reishauer in Switzerland. These chucks are unique in design and accuracy with no scroll, no cams but with screw, rack and pinion drive. The main features are:

- Body: Made of carbon steel forging and fitted with hardened and precision ground guides to ensure long lasting accuracy. The chucks are suitable for high spindle speeds.

- Screw: Made of alloy steel, hardened and precision ground on Reishauer thread grinding machine.

- Base Jaw: Made of alloy steel drop-forged. Rack profile is hardened and ground on Reishauer rack grinding machines.

- Racks: Made from drop forged alloy steel. The teeth for pinion and base jaws are hardened and ground on Reishauer rack grinding machines.

- Reversible Jaws: Made of drop-forged steel, hardened and ground. The jaws can be reset in less than one minute. Accuracy is obtained by grip grinding. It is also possible to mount soft jaws. It is advisable to take an additional set of base jaws for mounting soft jaws for higher productivity.

- Gripping Power: Maximum gripping power in minimum space. Results in less operator fatigue and deeper depth of cut.

- Accuracy: The chucks are one of the most accurate and reliable chucks available.

|

Chuck Model |

Units |

HF 150 |

HF 195 |

HF 250 |

HF 330 |

HF 400 |

|

Outside dia of Chuck |

mm |

150 |

195 |

250 |

330 |

400 |

|

Capacity external (Max.-Min.) |

mm |

150-4 |

195-8 |

250-8 |

330-18 |

400-20 |

|

Internal (Max.-Min.) |

mm |

150-45 |

195-70 |

250-80 |

330-112 |

400-120 |

|

Width of chuck |

mm |

54 |

66 |

83 |

97 |

105 |

|

Locating dia. for Flange |

mm |

138 |

180 |

230 |

312 |

380 |

|

Depth of location dia. |

mm |

4 |

5.5 |

5.5 |

6 |

6 |

|

Pitch circle dia. for Fixing bolts |

mm |

86 |

102 |

140 |

205 |

260 |

|

Through bore |

mm |

40 |

45 |

65 |

90 |

110 |

|

Size of fixing bolts |

mm |

M10 |

M12 |

M16 |

M22 |

M24 |

|

Bolting in depth |

mm |

15.5 |

17 |

20.5 |

22 |

26 |

|

Admissible max. speed |

RPM |

3000 |

2500 |

2000 |

1250 |

1000 |

|

Minimum flange width |

mm |

18 |

24 |

30 |

40 |

40 |

|

Weight of chuck |

kgs. |

7 |

15 |

30 |

61 |

61 |

Accuracy Chart

|

Testing Results in mm |

Tolerance as per I.S. 2876-78 |

Grade |

|

OD and face |

||

|

dia150 - dia250 |

0.05 |

0.02 |

|

dia330 - dia400 |

0.08 |

0.03 |

|

Run out on test mandrel held in jaws |

||

|

dia150 - dia250 |

0.075 |

0.015 |

|

dia330 |

0.075 |

0.02 |

|

dia400 |

0.075 |

0.03 |

|

Face runout over disc runout |

||

|

dia150 - dia250 |

0.075 |

0.01 |

|

dia400 |

0.075 |

0.02 |

Superior Precision and Versatility

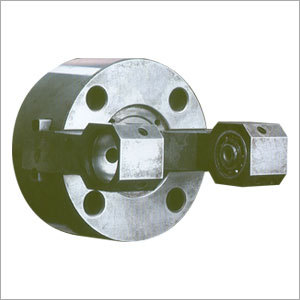

Quick Jaw Change Power Chucks are designed for applications demanding tight tolerances and consistent accuracy. With a chuck accuracy of 0.02 mm, users can maintain exceptional workpiece positioning, critical for both turning and milling operations. Their compatibility with various CNC machines and customizable gripping diameters up to 250 mm enhance operational versatility and suitability for diverse manufacturing environments.

Efficiency and Safety at the Forefront

Thanks to the jaw interlock safety mechanism and rapid jaw exchange feature, operational downtime is minimized, and operator safety is assured. This combination allows manufacturers to meet high-volume production targets while upholding safety standards. Low maintenance requirements further reduce machine idle times, contributing to overall productivity and cost efficiency.

FAQs of Quick Jaw Change Power Chucks:

Q: How do Quick Jaw Change Power Chucks improve production efficiency during machining operations?

A: The Quick Jaw Change Power Chucks enable rapid replacement of jaws, which drastically reduces changeover time between different jobs. This quick exchange process minimizes machine downtime and helps maintain continuous workflow, leading to higher overall productivity and faster turnaround.Q: What safety features are integrated into these power chucks?

A: These power chucks come equipped with a jaw interlock safety system, which ensures that the jaws remain securely locked during machine operation. This safety mechanism mitigates the risk of accidental jaw release or movement, protecting both the machine operator and the workpiece.Q: When should the chucks be maintained, and what is the maintenance process?

A: With their low-maintenance design, routine maintenance is only required at regular intervals as recommended in the user manual or when signs of wear are noticed. The process typically involves cleaning, inspecting the moving parts, and lubricating as specified, taking advantage of robust construction and precision ground finish for longevity.Q: Where are these chucks commonly used, and what types of machines are they compatible with?

A: Quick Jaw Change Power Chucks are primarily utilized in CNC lathe machines, turning centers, and milling machines across manufacturing industries. Their robust design and high-speed clamping capability make them suitable for both small workshops and large industrial setups.Q: What materials are used in the construction of these power chucks, and how does this benefit the user?

A: Constructed from high-grade alloy steel, these chucks offer exceptional durability and resistance to operational stresses. The precision ground finish further ensures smooth operation and consistent performance, translating to reduced maintenance needs and a longer product lifespan.Q: How is the clamping force adjusted, and what is the maximum capacity?

A: Clamping force is supplied via hydraulic or pneumatic power sources, depending on the chosen model. The maximum draw bar pull can reach up to 39 kN, and the chucks are designed to operate efficiently at high speeds, typically up to 8000 RPM, providing strong and reliable workpiece holding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Chuck Category

Quick Jaw Change Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Depends on Capacity

General Use : Machining, Clamping Workpieces

Feature : Other, Quick Change Jaw System, High Accuracy, Heavy Duty

Material : Other, Alloy Steel

Indexing Chuck

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Varies by model

General Use : Milling, Drilling, Grinding, Machining Centres

Feature : Other, High Precision, Rigid Construction, Smooth Indexing Mechanism

Material : Other, Alloy Steel

Chuck Spares

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Standard

General Use : Lathe Machines

Feature : Other, High Strength, Corrosion Resistant, Precise Construction

Material : Other, Metal

High Speed Power Chucks

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Varies by chuck size (example: 210mm, 250mm, 315mm)

General Use : CNC Turning Centers, Lathe Machines

Feature : Other, High gripping force, Stable Clamping, High Speed operation

Material : Other, Alloy Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese