Chuck Spares

Price 550-250000 INR/ Piece

Chuck Spares Specification

- Product Type

- Chuck Spares

- General Use

- Lathe Machines

- Material

- Metal

- Type

- Manual Chuck

- Capacity

- Standard

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- No. Of Jaws

- 4

- Dimension (L*W*H)

- Standard

- Feature

- High Strength, Corrosion Resistant, Precise Construction

- Color

- Silver/Grey

- Finishing Type

- Machined

- Durability

- Long lasting

- Maintenance

- Low

- Resistance

- Heat and wear resistant

- Compatibility

- Most standard lathe chucks

- Usage/Application

- Replacement parts for lathe machine chucks

- Packing Type

- Box

- Shape

- Custom

- Service Life

- Extended

- Texture

- Smooth surface

Chuck Spares Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

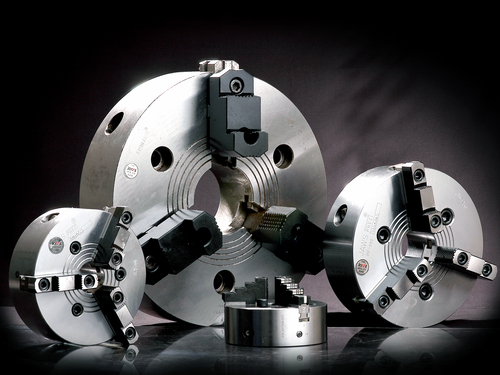

About Chuck Spares

We are a prominent organization, engaged in manufacturing, exporting and supplying premium quality Chuck Spares. These spares are very sturdy, non-corrosive and dimensionally accurate, therefore demanded by various industries in the market. Supreme grade alloy steel and other materials are sourced from the reputed vendors of the industry to manufacture these spares. To meet the diverse needs of our patrons, we offer the Chuck Spares in many sizes and specifications.

Other details:

The following soft jaws in flat as well as pointed typed are manufactured.

- 1.5mm x 60o serrations - These are suitable for Kitagawa, Pratt Burnerd, Howa, Schunk, etc chucks.

- 1/16" x 90o serrations.

- Various types of serrations like 1.5mm x 60o, 2mm x 60o, 2.5mm x 60o, 3mm x 60o, 3/32 x 90o, etc also manufactured.

- Tongue & groove type / Tenon type soft jaws.

- Teeth type soft jaws.

Hard Jaws

Hardness - HRC 58-60

Hard jaws with 1 or with 2 steps and the types as follows manufactured

- 1.5mm x 60o serrations - These are suitable for Kitagawa, Pratt Burnerd, Howa, Schunk, etc chucks.

- 1/16 x 90o serrations

- Facilities available to manufacture any serration be it 1.5mm x 60o, 2mm x 60o, 2.5mm x 60o, 3mm x 60o, 3/32 x 90o, etc

- Tongue and groove type hard jaws also known as tenon type hard jaws

- Teeth type hard jaws - for scroll operated chucks.

- Hard jaws as per customer drawings / requirements - special as well as standard.

Jaw and spares for PRECI chucks

- Supporting pivot

- Threaded bush

- Guide rail

- Spur Gear

- Plate

- Compression spring for indicating pin

- Handle socket

- Base Jaw

- Ring

- Compression spring for drop-in-pin

- Key handle

Precision Engineering for Reliability

Every Chuck Spare undergoes a meticulous machining process that delivers a smooth surface and precise construction. The machined finish guarantees an exceptional fit, supporting accuracy in various lathe machine operations and reducing equipment downtime due to part replacement.

Adaptable and Long-Lasting Performance

These spares boast compatibility with most standard lathe chucks, making them a flexible choice for different machine setups. Engineered for heat and wear resistance, Chuck Spares ensure stable performance and a long service life, even under demanding conditions.

Effortless Maintenance and Secure Packaging

Designed for low maintenance, Chuck Spares help streamline your workshop routines. Delivered in robust boxes, each component arrives protected from damage, ready for immediate use. Their silver/grey, corrosion-resistant finish adds utility and a professional appearance to your equipment.

FAQs of Chuck Spares:

Q: How do I select the correct Chuck Spares for my lathe machine?

A: To choose the right Chuck Spares, verify your lathes chuck type and jaw number (these are designed for 4-jaw manual chucks) and check that the dimensions match your existing components. These spares are compatible with most standard lathe chucks for seamless replacement.Q: What benefits do Chuck Spares offer compared to conventional spare parts?

A: Chuck Spares are manufactured from high-strength, corrosion-resistant metals with a precise machined finish. They are designed to deliver extended durability, low maintenance needs, and superior heat and wear resistance, resulting in improved machine performance and a longer service lifespan.Q: When should I consider replacing parts with Chuck Spares?

A: Consider using Chuck Spares whenever you notice signs of wear, inaccuracy, or reduced grip in your lathe chuck. Timely replacement ensures continued precision, operational safety, and prevents costly downtime.Q: Where are Chuck Spares typically used?

A: Chuck Spares are intended for use in manual lathe machines in industrial workshops, manufacturing units, and repair facilities. Thanks to their standard and custom shape options, they cater to a variety of general and specialized lathe applications.Q: What is the process for installing Chuck Spares?

A: Begin by disconnecting the lathe from its power source. Carefully remove worn components, clean the mounting surfaces, and fit the new Chuck Spares securely according to the lathe manufacturers instructions. Their precise construction facilitates easy and accurate installation.Q: How does the finishing type and texture of Chuck Spares contribute to their performance?

A: The machined finish and smooth surface of Chuck Spares ensure minimal friction and a precise fit, which aids in achieving accurate machining results. The finish also adds to the components longevity and helps maintain equipment cleanliness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Chuck Category

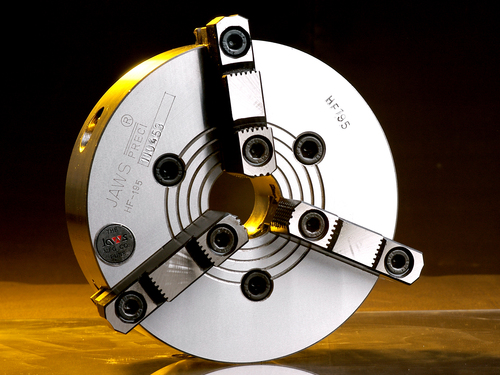

Quick Jaw Change Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, Quick Change Jaw System, High Accuracy, Heavy Duty

Color : Metallic Grey

Type : Lathe Chuck

No. Of Jaws : 3 or 4 Jaws

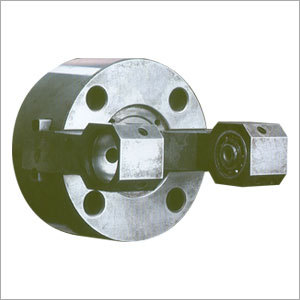

Indexing Chuck

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, High Precision, Rigid Construction, Smooth Indexing Mechanism

Color : Metallic Grey

Type : Other, Manual

No. Of Jaws : 3 or 4

Quick Jaw Change Power Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, Quick Jaw Change, High Clamping Force, High Speed, Accurate Positioning

Color : Silver/Grey

Type : Other, Power Operated

No. Of Jaws : 3

High Speed Power Chucks

Minimum Order Quantity : 1 Piece

Feature : Other, High gripping force, Stable Clamping, High Speed operation

Color : Metallic Grey

Type : Other, Power Operated Chuck

No. Of Jaws : 3

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese