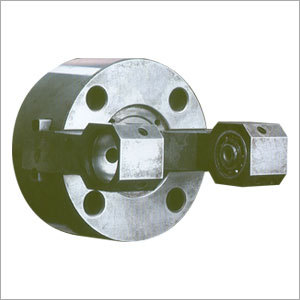

Indexing Chuck

Price 550-250000 INR/ Piece

Indexing Chuck Specification

- Product Type

- Indexing Chuck

- General Use

- Milling, Drilling, Grinding, Machining Centres

- Material

- Alloy Steel

- Type

- Manual

- Capacity

- 100 mm to 250 mm

- Weight (kg)

- 8 to 45 kg (varies with model)

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- No. Of Jaws

- 3 or 4

- Power Source

- Manual

- Dimension (L*W*H)

- Varies by model

- Feature

- High Precision, Rigid Construction, Smooth Indexing Mechanism

- Color

- Metallic Grey

Indexing Chuck Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

About Indexing Chuck

We are engaged in manufacturing, supply and export top quality Indexing Chuck. We manufacture these chucks by making use of quality components and materials obtained from the trustworthy vendors of the industry. These chucks are specially designed to fit the mounting pads aligned on the jaws to ensure concentricity. The offered Indexing Chuck is manufactured by our experienced team members, following all the norms and parameters laid by the industry.

Other details:

Parts which require multi-side machining may require 2 or more set-ups. It means,

- elaborate fixtures involving references and high accuracies.

- Loss of concentricity at various stages.

- Inaccuracies involved in mounting.

- Time lost in mounting each component, number of times.

- Loss of machine hours is set ups, set up approvals and rejections.

To Index:

- Pull clutch lever

- Turn the part partly with hand.

- Release the lever

- Continue to turn the part until you hear a click assuring that the part has indexed exactly by 90 or 180 degrees, (provision can be made for angles required).

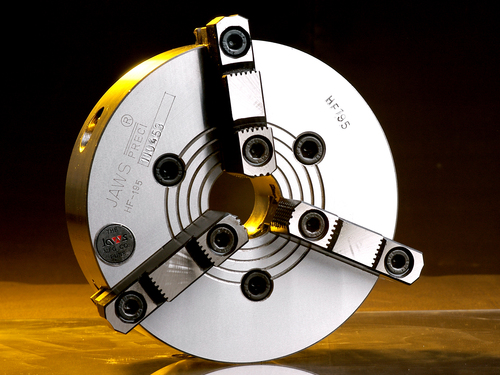

Outstanding Indexing Precision

Achieve exacting results with 0.02 mm indexing accuracy. This manual chuck delivers repeatable, reliable indexing for demanding machining processes, improving overall production quality in mills, grinders, and drill machines. Its corrosion-resistant alloy steel body stands up to tough shop conditions, while the advanced design provides both stability and smooth operation.

Versatile Position Options & Application

Available models support 24, 36, 48, or 72 indexing positions, catering to multiple machining requirements. The direct mount design makes integration with your machine table seamless, while the sturdy mechanism is adaptable for a range of tasksmilling, drilling, grinding, or machining centreswhere precise work-holding and rotating are essential.

User-Friendly Manual Operation

Eliminate complexity with lever-driven manual indexing. The straightforward operation allows quick adjustment and secure clamping, reducing setup time while maintaining accuracy. No electricity or PLC control is required, making this chuck ideal for workshops seeking reliable manual solutions without automation.

FAQs of Indexing Chuck:

Q: How accurate is the indexing mechanism of this manual chuck?

A: The indexing mechanism provides a high indexing accuracy of 0.02 mm, allowing for extremely precise positioning during milling, drilling, grinding, and other machining operations.Q: What indexing positions does the chuck support?

A: Depending on the model, the chuck offers 24, 36, 48, or 72 indexing positions. This flexibility makes it suitable for a variety of machining requirements and component geometries.Q: Where can this indexing chuck be mounted?

A: This manual indexing chuck is designed for direct mounting onto a machine table, streamlining installation and ensuring stability during operation.Q: What is the process for changing the indexed position?

A: To change the indexed position, simply operate the manual lever which disengages and re-engages the indexing mechanism. This allows fast, smooth, and secure transitions between positions without the need for computerized or automatic controls.Q: What are the main benefits of the through-hole clamp style?

A: The through-hole clamp style ensures workpieces of varying sizes can be securely clamped, adds versatility for different machining applications, and improves access for long components.Q: Is the manual indexing chuck suitable for automated operations or controlled via PLC?

A: No, this is a manually operated chuck and does not support automation or PLC controls. It is specifically designed for manual use in settings where digital control is not required.Q: Which materials and finishes are used in the construction of the chuck?

A: The chuck is crafted from high-quality alloy steel, featuring a corrosion-resistant finish to enhance durability and maintain performance in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

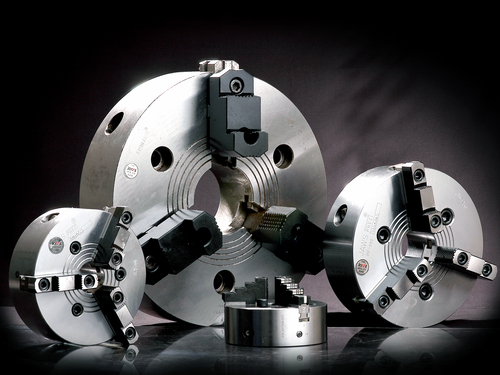

More Products in CNC Chuck Category

Quick Jaw Change Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Material : Other, Alloy Steel

No. Of Jaws : 3 or 4 Jaws

General Use : Machining, Clamping Workpieces

Chuck Spares

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Material : Other, Metal

No. Of Jaws : 4

General Use : Lathe Machines

Quick Jaw Change Power Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Material : Other, Alloy Steel Body

No. Of Jaws : 3

General Use : CNC Lathe Machines, Turning Centers, Milling Machines

High Speed Power Chucks

Minimum Order Quantity : 1 Piece

Automatic : Yes

Material : Other, Alloy Steel

No. Of Jaws : 3

General Use : CNC Turning Centers, Lathe Machines

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese