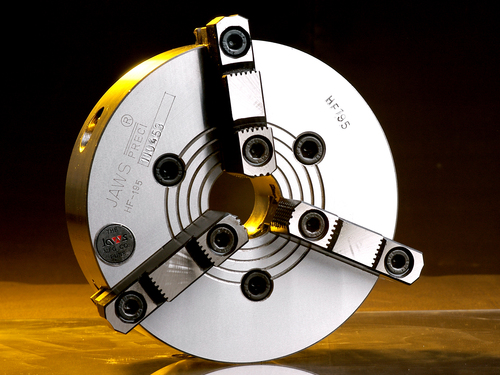

High Speed Power Chucks

High Speed Power Chucks Specification

- Product Type

- High Speed Power Chucks

- General Use

- CNC Turning Centers, Lathe Machines

- Material

- Alloy Steel

- Type

- Power Operated Chuck

- Computerized

- No

- Automatic

- Yes

- No. Of Jaws

- 3

- Power Source

- Hydraulic or Pneumatic

- Voltage

- Hydraulic/Pneumatic (no voltage required)

- Dimension (L*W*H)

- Varies by chuck size (example: 210mm, 250mm, 315mm)

- Feature

- High gripping force, Stable Clamping, High Speed operation

- Color

- Metallic Grey

- Mounting Type

- Direct Mount/Adapter Plate

- Accuracy

- 0.02 mm

- Clamping Range

- 60 mm to 300 mm

- Hardness (Jaws/Body)

- HRC 55+/HRC 40+

- Application

- Machining, Heavy Duty Clamping

- Suitable For

- CNC, VMC, HMC, Special Purpose Machines

High Speed Power Chucks Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

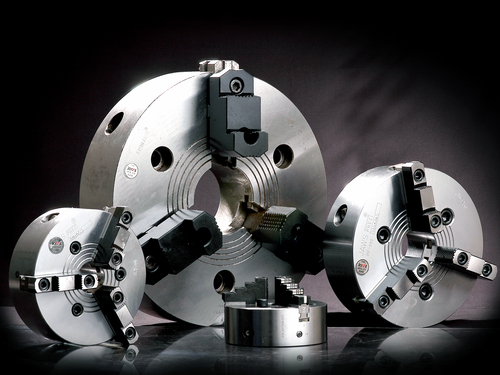

About High Speed Power Chucks

Our customers can avail from us premium quality High Speed Power Chucks. These power chucks are manufacture by our highly trained professionals in our huge infrastructure facility using high-grade alloy steel, obtained from the reputed vendors of the market. Offered power chucks are easy to operate as material removal, clamping and declamping is easy and time saving. Keeping in mind the wide demands of our clients, we are able to offer the High Speed Power Chucks in many specifications.

Other details:

Power chucks in 2, 3, 4, 5, 6, 8 and 12-jaw types are manufactured in close as well as hollow types.

Range

-

80mm to 1000mm in close centre type

-

135mm to 800mm in high speed hollow type

-

The chuck body is made of alloy steel-robust construction, the hard jaws, base jaws, wedge are case hardened and ground to suit customer needs.

Features

-

Front opening design saves cleaning and servicing time since chuck does not need to be taken off from spindle.

-

Clamping and declamping time is saved

-

Higher rate of material removal is possible

-

Keying time saved, hence operator fatigue is also eliminated

-

Repeatability maintained within 30 microns.

Technical Features

-

Body : Alloy Steel

-

Guide ways : Hardened and ground on all surfaces

-

Base jaws : Guided in deep, wide, hardened slots on the chuck body with serration on the top surface

-

Hard jaws : Case hardened and ground.

Specifications

| Chuck dia in mm | 135 | 165 | 210 | 250 | 315 | 400 | 500 |

| dia A | 135 | 165 | 210 | 250 | 315 | 400 | 500 |

| dia B | 30 | 39 | 52 | 70 | 95 | 130 | 140 |

| dia M H6 | 110 | 140 | 170 | 220 | 300 | 380 | 380 |

| D (PCD) | 82.6 | 104.8 | 133.4 | 171.5 | 235 | 330.2 | 330.2 |

| E x 3 nos. | M10 | M10 | M12 | M16 | M20 | M20 | M20 |

| dia F | 40 | 48 | 63 | 78 | 100 | 142 | 142 |

| G | M32x3 | M39x1.5 | M55x2 | M72x2 | M92x2 | M133x2 | M133x2 |

| H | 64 | 87 | 96 | 106 | 100 | 130 | 130 |

| a | 39 | 49 | 59 | 75 | 98 | 118 | 118 |

| b H 7 | 10 | 12 | 17 | 21 | 21 | 25.5 | 25.5 |

| I | 60 | 83 | 92 | 101 | 95 | 125 | 125 |

| C | 4 | 5 | 6 | 6 | 6 | 6 | 7 |

| J | 40 | 52 | 55 | 65 | 64 | 80 | 80 |

| Serration 90o | 1/16" | 1/16" | 1/16" | 1/16" | 1/16" | 3/32" | 3/32" |

| Jaw Stroke (On Dia) | 6mm | 10mm | 10mm | 11mm | 11mm | 12mm | 12mm |

| Min Engagement | 12 | 12 | 16 | 18 | 20 | 20 | 22 |

| Runout on chuck OD | 0.02 | 0.02 | 0.02 | 0.02 | 0.3 | 0.03 | 0.03 |

| RPM | 6000 | 5500 | 5000 | 4000 | 3000 | 2500 | 2000 |

| Max Drawtube Pull (kgf) | 2500 | 3000 | 4000 | 6000 | 6000 | 9000 | 9000 |

| Max Gripping Force (kN) | 50 | 60 | 80 | 120 | 130 | 200 | 210 |

| Weight (Kgs) | 5.8 | 7.5 | 16 | 26 | 38 | 90 | 150 |

Precise Clamping for Advanced Machining

Engineered for CNC turning centers and lathe machines, these chucks ensure reliable, accurate workholding. The high gripping force, combined with stable, high-speed clamping, delivers superior performance even in heavy-duty operations. Enhanced accuracy and robust construction make them essential for precise machined components.

Adaptable Mounting for Versatile Applications

You can choose direct mount or adapter plate set-ups to fit your machine. This adaptability enables seamless integration with CNC, VMC, HMC, or special purpose machines. With various sizes available, these power chucks can support a broad range of industrial clamping needs.

Built for Durability and High Performance

Forged from alloy steel and engineered with hardened jaws and bodies, these power chucks are built to withstand demanding production environments. The automatic mechanism and hydraulic or pneumatic actuation make them efficient, reliable, and easy to operate, extending service life and minimizing downtime.

FAQs of High Speed Power Chucks:

Q: How do I select the right power chuck size for my application?

A: Choose the power chuck size based on your workpiece dimensions and clamping requirements. The available range (60 mm to 300 mm) accommodates a variety of machining operations, ensuring secure clamping and optimal performance.Q: What is the process for mounting these power chucks to my CNC machine?

A: These chucks can be directly mounted or attached using an adapter plate, depending on your machines spindle configuration. Installation should follow manufacturer guidelines for safe and precise alignment to maintain performance and accuracy.Q: What are the main benefits of using high-speed power chucks?

A: These chucks offer high gripping force, rapid clamping, exceptional accuracy ( 0.02 mm), and enhanced stability. Their durable design ensures reliability for demanding applications, reducing setup times and improving machining efficiency.Q: When should I use hydraulic or pneumatic actuation for my power chuck?

A: Select hydraulic actuation for high clamping force and larger workpieces, and pneumatic for quick, energy-efficient clamping of lighter components. Your choice depends on specific machining needs and available infrastructure.Q: Where are these chucks typically used?

A: Our high-speed power chucks are widely used in CNC turning centers, lathe machines, VMCs, HMCs, and special purpose machines in industries that demand precise, heavy-duty machining and secure workpiece clamping.Q: What maintenance is required to ensure prolonged chuck performance?

A: Routine cleaning, regular inspection for wear, and proper lubrication are essential. Periodic checks of hydraulic or pneumatic connections help maintain safety, accuracy, and operational longevity of the power chuck.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Chuck Category

Indexing Chuck

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Metallic Grey

Automatic : No

General Use : Milling, Drilling, Grinding, Machining Centres

Quick Jaw Change Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Metallic Grey

Automatic : Yes

General Use : Machining, Clamping Workpieces

Chuck Spares

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Silver/Grey

Automatic : No

General Use : Lathe Machines

Quick Jaw Change Power Chucks

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Silver/Grey

Automatic : Yes

General Use : CNC Lathe Machines, Turning Centers, Milling Machines

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese