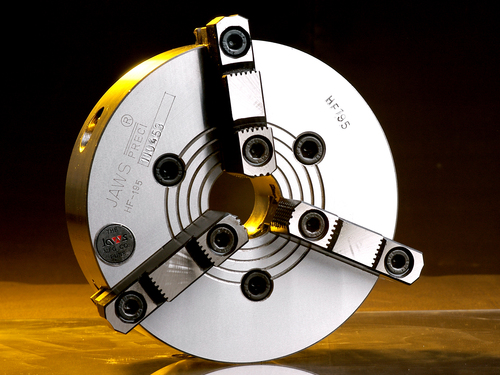

क्विक जॉ चेंज चक्स

उत्पाद विवरण:

क्विक जॉ चेंज चक्स मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

- टुकड़ा/टुकड़े

क्विक जॉ चेंज चक्स व्यापार सूचना

- 100 प्रति दिन

- 2-7 दिन

उत्पाद वर्णन

To meet our clients' requirements, we are able to manufacture, supply and export Quick Jaw Change Chucks. Our vendors supply us with high quality carbon steel and stainless alloy steel to manufacture long lasting and non-corrosive chuck components. These chucks consists of screw, rack and pinion drive to ensure easy installation and high performance. The offered Quick Jaw Change Chucks are available in many sizes and specification for the various requirements of our clients.

Other details:

PRECI chucks earlier manufactured by Reishauer in Switzerland. These chucks are unique in design and accuracy with no scroll, no cams but with screw, rack and pinion drive. The main features are:

- Body: Made of carbon steel forging and fitted with hardened and precision ground guides to ensure long lasting accuracy. The chucks are suitable for high spindle speeds.

- Screw: Made of alloy steel, hardened and precision ground on Reishauer thread grinding machine.

- Base Jaw: Made of alloy steel drop-forged. Rack profile is hardened and ground on Reishauer rack grinding machines.

- Racks: Made from drop forged alloy steel. The teeth for pinion and base jaws are hardened and ground on Reishauer rack grinding machines.

- Reversible Jaws: Made of drop-forged steel, hardened and ground. The jaws can be reset in less than one minute. Accuracy is obtained by grip grinding. It is also possible to mount soft jaws. It is advisable to take an additional set of base jaws for mounting soft jaws for higher productivity.

- Gripping Power: Maximum gripping power in minimum space. Results in less operator fatigue and deeper depth of cut.

- Accuracy: The chucks are one of the most accurate and reliable chucks available.

| Chuck Model | Units | HF 150 | HF 195 | HF 250 | HF 330 | HF 400 |

| Outside dia of Chuck | mm | 150 | 195 | 250 | 330 | 400 |

| Capacity external (Max.-Min.) | mm | 150-4 | 195-8 | 250-8 | 330-18 | 400-20 |

| Internal (Max.-Min.) | mm | 150-45 | 195-70 | 250-80 | 330-112 | 400-120 |

| Width of chuck | mm | 54 | 66 | 83 | 97 | 105 |

| Locating dia. for Flange | mm | 138 | 180 | 230 | 312 | 380 |

| Depth of location dia. | mm | 4 | 5.5 | 5.5 | 6 | 6 |

| Pitch circle dia. for Fixing bolts | mm | 86 | 102 | 140 | 205 | 260 |

| Through bore | mm | 40 | 45 | 65 | 90 | 110 |

| Size of fixing bolts | mm | M10 | M12 | M16 | M22 | M24 |

| Bolting in depth | mm | 15.5 | 17 | 20.5 | 22 | 26 |

| Admissible max. speed | RPM | 3000 | 2500 | 2000 | 1250 | 1000 |

| Minimum flange width | mm | 18 | 24 | 30 | 40 | 40 |

| Weight of chuck | kgs. | 7 | 15 | 30 | 61 | 61 |

Accuracy Chart

| Testing Results in mm | Tolerance as per I.S. 2876-78 | Grade |

| OD and face | ||

| dia150 - dia250 | 0.05 | 0.02 |

| dia330 - dia400 | 0.08 | 0.03 |

| Run out on test mandrel held in jaws | ||

| dia150 - dia250 | 0.075 | 0.015 |

| dia330 | 0.075 | 0.02 |

| dia400 | 0.075 | 0.03 |

| Face runout over disc runout | ||

| dia150 - dia250 | 0.075 | 0.01 |

| dia400 | 0.075 | 0.02 |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+