à¤à¥à¤à¤¼ à¤à¤à¥à¤¸à¥à¤à¤à¥à¤°à¤¿à¤ à¤à¤®à¥à¤ªà¥à¤à¤¸à¥à¤à¤¿à¤à¤ à¤à¤

Price 550-250000 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

à¤à¥à¤à¤¼ à¤à¤à¥à¤¸à¥à¤à¤à¥à¤°à¤¿à¤ à¤à¤®à¥à¤ªà¥à¤à¤¸à¥à¤à¤¿à¤à¤ à¤à¤ Specification

- प्रॉडक्ट टाइप

- Eccentric Compensating Chuck

- सामान्य उपयोग

- Precision Lathe and CNC Turning Applications

- मटेरियल

- टाइप करें

- क्षमता

- Up to 250 mm (varies by model)

- वजन (किग्रा)

- Approx 18-32 kg (model dependent)

- कम्प्यूटरीकृत

- ऑटोमेटिक

- नहीं। जॉज़ का

- 3 (Eccentric Compensating)

- पावर सोर्स

- आयाम (एल* डब्ल्यू* एच)

- 220 mm x 220 mm x 130 mm (approx, varies by size)

- फ़ीचर

- रंग

- Metallic Silver with Black Accents

à¤à¥à¤à¤¼ à¤à¤à¥à¤¸à¥à¤à¤à¥à¤°à¤¿à¤ à¤à¤®à¥à¤ªà¥à¤à¤¸à¥à¤à¤¿à¤à¤ à¤à¤ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- 100 प्रति दिन

- डिलीवरी का समय

- 2-7 दिन

About à¤à¥à¤à¤¼ à¤à¤à¥à¤¸à¥à¤à¤à¥à¤°à¤¿à¤ à¤à¤®à¥à¤ªà¥à¤à¤¸à¥à¤à¤¿à¤à¤ à¤à¤

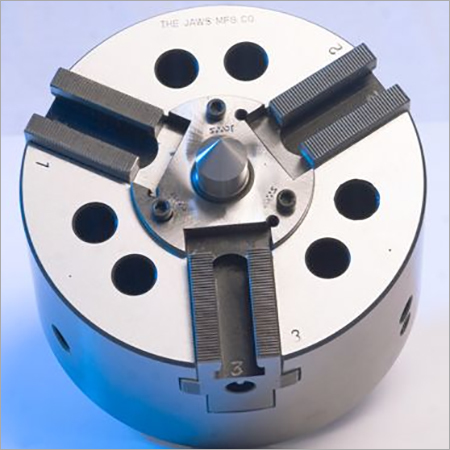

The Jaws Eccentric Compensating Chuck is a must-have crackerjack solution for precision lathe and CNC turning applications. Crafted from immaculate, hardened alloy steel, its polished, corrosion-resistant surface guarantees longevity in rigorous industrial workshops. Benefit from its radial compensating jaw movement, providing immaculate grip on irregular and non-concentric workpieces. With adjustable eccentricity and runout accuracy of 0.01 mm, this chuck offers brilliant savings and a true bargain for manufacturers. Experience high gripping force, replaceable jaws, and low maintenance, all packed into a stylish metallic silver bodyideal for semi-automatic and manual operations.

Versatile Application Areas and Competitive Edge

Ideal for industrial workshops and CNC centers, the Jaws Eccentric Compensating Chuck excels in primary applications such as irregular and non-concentric workpiece clamping. Its use in precision lathe operations makes it essential for plant setups demanding consistency and reliability. The standout competitive advantages include self-centering capability, precise compensation, and robust construction. With replaceable jaws, low maintenance needs, and adjustable eccentricity, this workholding chuck ensures flawless operation, cementing its value for modern manufacturing environments.

Domestic Market Reach and Prompt Supply

Jaws Eccentric Compensating Chuck enjoys robust demand in Indias key domestic markets, thanks to its competitive list price and proven performance. Exporters and manufacturers ensure express shipping through strategic FOB ports, maximizing supply ability to meet urgent bulk orders. With an expanding export market, customers benefit from quick order processing and reliable fulfillment. The manufacturers agility in logistics enables delivery tailored to the buyers requirements, making this high-performance chuck a trusted choice for domestic and international clients alike.

Versatile Application Areas and Competitive Edge

Ideal for industrial workshops and CNC centers, the Jaws Eccentric Compensating Chuck excels in primary applications such as irregular and non-concentric workpiece clamping. Its use in precision lathe operations makes it essential for plant setups demanding consistency and reliability. The standout competitive advantages include self-centering capability, precise compensation, and robust construction. With replaceable jaws, low maintenance needs, and adjustable eccentricity, this workholding chuck ensures flawless operation, cementing its value for modern manufacturing environments.

Domestic Market Reach and Prompt Supply

Jaws Eccentric Compensating Chuck enjoys robust demand in Indias key domestic markets, thanks to its competitive list price and proven performance. Exporters and manufacturers ensure express shipping through strategic FOB ports, maximizing supply ability to meet urgent bulk orders. With an expanding export market, customers benefit from quick order processing and reliable fulfillment. The manufacturers agility in logistics enables delivery tailored to the buyers requirements, making this high-performance chuck a trusted choice for domestic and international clients alike.

FAQs of Jaws Eccentiric Compensating Chuck:

Q: How does the Jaws Eccentric Compensating Chuck enhance workpiece clamping for irregular shapes?

A: Its radial compensating jaw movement and adjustable eccentricity provide crackerjack precision, allowing secure gripping of non-concentric and irregular workpieces, which reduces runout and boosts machining accuracy.Q: What are the primary benefits of using this chuck in CNC turning applications?

A: The chuck delivers impeccable repeatability, self-centering, high gripping force, and easy adjustmentensuring immaculate finished products, minimal user intervention, and superb performance in precision CNC operations.Q: When is lubrication required for optimal maintenance?

A: Routine use necessitates regular lubrication to maintain low maintenance and ensure the chucks polished smooth jaw operation, safeguarding against wear and prolonging service life, particularly in high-speed industrial settings.Q: Where can this chuck be effectively used?

A: It is designed for industrial workshops, CNC centers, and precision lathe operations where reliable workholding is crucial, making it suitable for environments demanding top-tier accuracy and robust gripping capabilities.Q: What is the overall process for mounting the chuck in a workshop setting?

A: The chuck offers both Direct Mount and Adapter Mount styles; installation requires securing the unit onto the lathe spindle, followed by jaw adjustment using a lever or key for snug, compensated clamping.Q: How does express shipping contribute to timely delivery for large orders?

A: Express shipping ensures rapid transit from FOB port to destination, minimizing downtime and enabling manufacturers and suppliers to stay competitive while meeting urgent customer requirements efficiently.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese