CHP 200 सिलà¥à¤à¤¡à¤° à¤à¤à¤à¥à¤à¥à¤°à¥à¤à¥à¤¡ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ à¤à¥à¤²à¥à¤ à¤à¤

Price 550-250000 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

CHP 200 सिलà¥à¤à¤¡à¤° à¤à¤à¤à¥à¤à¥à¤°à¥à¤à¥à¤¡ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ à¤à¥à¤²à¥à¤ à¤à¤ Specification

- प्रॉडक्ट टाइप

- Cylinder Integrated Hydraulic Collet Chuck

- सामान्य उपयोग

- CNC Turning Centers, Precision Machining

- मटेरियल

- टाइप करें

- क्षमता

- 5-60 mm (collet range)

- वजन (किग्रा)

- Approx. 25 kg

- कम्प्यूटरीकृत

- ऑटोमेटिक

- नहीं। जॉज़ का

- Collet-type (no jaws)

- पावर सोर्स

- वोल्टेज

- Hydraulic, not electrical

- आयाम (एल* डब्ल्यू* एच)

- Approx. 260 x 200 x 200 mm

- फ़ीचर

- रंग

- Standard Metal Finish (Polished Steel)

CHP 200 सिलà¥à¤à¤¡à¤° à¤à¤à¤à¥à¤à¥à¤°à¥à¤à¥à¤¡ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ à¤à¥à¤²à¥à¤ à¤à¤ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- 100 प्रति दिन

- डिलीवरी का समय

- 2-7 दिन

About CHP 200 सिलà¥à¤à¤¡à¤° à¤à¤à¤à¥à¤à¥à¤°à¥à¤à¥à¤¡ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ à¤à¥à¤²à¥à¤ à¤à¤

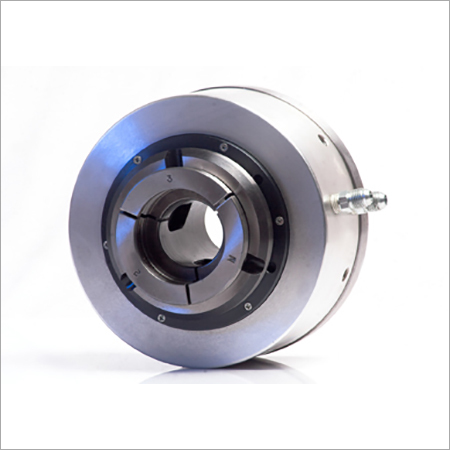

The CHP 200 Cylinder Integrated Hydraulic Collet Chuck stands as a scarce opportunity for those seeking unassailable precision in CNC turning and precision machining. Its direct spindle nose mounting, compatible with A2-6/A2-8, and an invincible max RPM of 4500 ensure triumphant productivity. Popular among industry experts for high gripping force and accuracy (0.01 mm), its high grade alloy steel construction offers a body hardness of HRC 60-62. Sealed for low maintenance and integrated for compact power, this product-in-demand is engineered for efficiency and reliability.

Optimized Usage & Applications for Elite Precision

The CHP 200 Cylinder Integrated Hydraulic Collet Chuck is ideally suited for high precision and high productivity applications. Specifically crafted for CNC Turning Centers and precision machining tasks, its collet-type designaccommodating a 5-60 mm rangedelivers unmatched performance for bar feeding. Its rust preventive, precision ground finish and hydraulic actuation make it indispensable for manufacturers demanding consistent, reliable, and accurate results under challenging production schedules.

Smooth Dispatching, Reliable Valuation & Global Transport सेवाएं

Every CHP 200 Cylinder Integrated Hydraulic Collet Chuck is promptly dispatched post rigorous valuation and certifications, confirming its industry-leading reliability. We utilize trusted transport services from our India-based FOB ports, ensuring efficient and secure delivery on every order. Clients benefit from detailed documentation supporting the products authenticity and compliance. This streamlined process guarantees timely shipment and safe arrival of your critical machining equipment anywhere, supporting continuous production flow.

Optimized Usage & Applications for Elite Precision

The CHP 200 Cylinder Integrated Hydraulic Collet Chuck is ideally suited for high precision and high productivity applications. Specifically crafted for CNC Turning Centers and precision machining tasks, its collet-type designaccommodating a 5-60 mm rangedelivers unmatched performance for bar feeding. Its rust preventive, precision ground finish and hydraulic actuation make it indispensable for manufacturers demanding consistent, reliable, and accurate results under challenging production schedules.

Smooth Dispatching, Reliable Valuation & Global Transport सेवाएं

Every CHP 200 Cylinder Integrated Hydraulic Collet Chuck is promptly dispatched post rigorous valuation and certifications, confirming its industry-leading reliability. We utilize trusted transport services from our India-based FOB ports, ensuring efficient and secure delivery on every order. Clients benefit from detailed documentation supporting the products authenticity and compliance. This streamlined process guarantees timely shipment and safe arrival of your critical machining equipment anywhere, supporting continuous production flow.

FAQs of CHP 200 Cylinder Integrated Hydraulic Collet Chuck:

Q: How does the integrated cylinder design benefit the CHP 200 Collet Chucks operation?

A: The integrated cylinder design leads to a more compact construction, enhancing machine stability and enabling high gripping force. This ensures both high accuracy and smoother operation, while also contributing to lower maintenance requirements due to fewer external parts.Q: What types of applications is the CHP 200 Collet Chuck suitable for?

A: The CHP 200 is best suited for CNC Turning Centers, precision machining, and any operation requiring high accuracy, reliable bar feeding, and a collet range accommodating diameters from 5 to 60 mm.Q: When can I expect the delivery of the CHP 200 after placing an order?

A: Once your order is placed and payment is confirmed, the product undergoes final valuation and certification before dispatching. Lead times may vary depending on location and transport services, but prompt processing from our Indian FOB port ensures timely delivery.Q: What makes the CHP 200 Collet Chuck popular among manufacturers?

A: Its popularity arises from invincible accuracy (0.01 mm), robust body hardness (HRC 60-62), and low maintenance needs due to its sealed, rust-preventive construction. The products unassailable reliability in high productivity environments makes it a preferred choice.Q: Where is the CHP 200 Collet Chuck manufactured and exported from?

A: The CHP 200 is engineered, manufactured, and exported by a reputable supplier based in India, with worldwide shipping using secure, documented transport services from established FOB ports.Q: What is the process for the installation of the CHP 200 Collet Chuck?

A: Installation is straightforward via direct spindle nose mounting, compatible with A2-6 and A2-8 spindle noses. The integrated draw tube connection streamlines setup, supporting quick and efficient commissioning for production use.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in निर्मित सिलेंडर रोटरी पावर चक Category

JAP 200 सिलेंडर इंटीग्रेटेड एयर कोलेट चक

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

मूल्य की इकाई : टुकड़ा/टुकड़े

कम्प्यूटरीकृत : No

फ़ीचर : ,

एयर हाइड्रो रोटरी पावर चक

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

मूल्य की इकाई : टुकड़ा/टुकड़े

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें