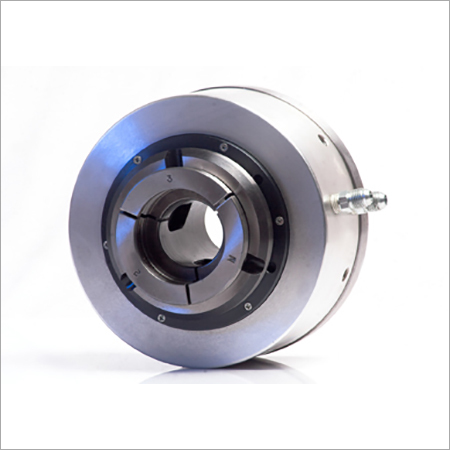

JAP 200 Cylinder Integrated Air Collet Chuck

Price 550-250000 INR/ Piece

MOQ : 1 Piece

JAP 200 Cylinder Integrated Air Collet Chuck Specification

- Product Type

- Cylinder Integrated Air Collet Chuck

- General Use

- Holding and clamping workpieces for CNC lathes and machine tools

- Material

- Alloy Steel

- Type

- Pneumatic

- Capacity

- 200 mm

- Weight (kg)

- Approx. 13-15 kg

- Computerized

- No

- Automatic

- Yes

- PLC Control

- No

- No. Of Jaws

- 1 (Collet Type)

- Power Source

- Compressed Air

- Voltage

- 0 (Pneumatic operation, no voltage required)

- Dimension (L*W*H)

- Approx. 230 mm x 200 mm x 100 mm

- Feature

- High gripping accuracy, compact design, quick change capability

- Color

- Silver / Metallic Grey

JAP 200 Cylinder Integrated Air Collet Chuck Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

About JAP 200 Cylinder Integrated Air Collet Chuck

Redeem the champion among collet chucks the JAP 200 Cylinder Integrated Air Collet Chuck, offering a glorious union of strength and precision. With a ravishing hard chrome-plated body and robust alloy steel construction, this pneumatic marvel delivers an unbeatable price for those seeking the best price-to-performance ratio. Enjoy up to 38 kN clamping force, excellent runout accuracy (0.02 mm), and seamless integration with most CNC and manual lathes. Its centralized lubrication port, quick change feature, and compact, automatic operation make it the undisputed leader for automating your turning, milling, and drilling operations. Secure magnificent results with this superior tool.

Versatile Usage & Robust Application

The JAP 200 Cylinder Integrated Air Collet Chuck shines in demanding industrial settings. Designed as a pneumatic, automatic clamping system, it excels at securely holding workpieces on CNC and manual lathes. Its application surfaces include precision-turned, milled, or drilled metal components, while the media involved is compressed air supplied via a G1/4" port. Ideal for manufacturers and machinists seeking dependable performance and superior repeatability across various industrial applications.

Sample Policy & Efficient Delivery Framework

Our sample policy for the JAP 200 Cylinder Integrated Air Collet Chuck ensures transparencysamples are available upon formal estimate approval and proposal amount agreement. Packing & dispatch are handled with utmost care for domestic deliveries across India, ensuring safe transit. Customers are provided accurate delivery timeframes based on order quantities. The main domestic market includes key industrial hubs, ensuring prompt and professional service tailored to your needs.

Versatile Usage & Robust Application

The JAP 200 Cylinder Integrated Air Collet Chuck shines in demanding industrial settings. Designed as a pneumatic, automatic clamping system, it excels at securely holding workpieces on CNC and manual lathes. Its application surfaces include precision-turned, milled, or drilled metal components, while the media involved is compressed air supplied via a G1/4" port. Ideal for manufacturers and machinists seeking dependable performance and superior repeatability across various industrial applications.

Sample Policy & Efficient Delivery Framework

Our sample policy for the JAP 200 Cylinder Integrated Air Collet Chuck ensures transparencysamples are available upon formal estimate approval and proposal amount agreement. Packing & dispatch are handled with utmost care for domestic deliveries across India, ensuring safe transit. Customers are provided accurate delivery timeframes based on order quantities. The main domestic market includes key industrial hubs, ensuring prompt and professional service tailored to your needs.

FAQs of JAP 200 Cylinder Integrated Air Collet Chuck:

Q: How do I install the JAP 200 Cylinder Integrated Air Collet Chuck on my lathe?

A: Installation is straightforward, as the chuck is compatible with most CNC and manual lathes featuring a 200mm mounting. It can be front or back mounted directly onto the spindle nose. Detailed instructions are included in the product manual for seamless integration.Q: What are the key benefits of using this air collet chuck in machining operations?

A: The chuck offers high gripping accuracy, quick-change capability, and a compact design. Its automatic pneumatic operation ensures efficient, consistent clampingideal for automating turning, milling, and drilling tasks. Additionally, central grease lubrication and corrosion-resistant surface ensure longevity and easy maintenance.Q: When should I consider replacing or servicing the collet chuck?

A: Routine maintenance is recommended based on operational frequency. Service or replace the collet chuck if you notice diminished clamping force, increased runout, or visible wear. Regular lubrication via the provided port enhances its lifespan and performance.Q: Where is this product normally used?

A: This air collet chuck is predominantly used in industrial machine shops, manufacturing units, and tool rooms, especially for high-precision metalworking tasks involving CNC lathes and machine tools throughout India.Q: What is the process for requesting a sample or estimate?

A: To request a sample or estimate, contact our sales team with your technical requirements. Upon approval of the proposal amount, packing & dispatch of the sample can be arranged. Delivery timelines are communicated transparently based on location and order size.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Built In Cylinder Rotary Power Chuck Category

CHP 200 Cylinder Integrated Hydraulic Collet Chuck

Price 550-250000 INR / Piece

Minimum Order Quantity : 1 Piece

No. Of Jaws : Collettype (no jaws)

Material : Other, High Grade Alloy Steel

Feature : Other, Cylinder integrated for compact construction, high accuracy, high gripping force, low maintenance

General Use : CNC Turning Centers, Precision Machining

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS