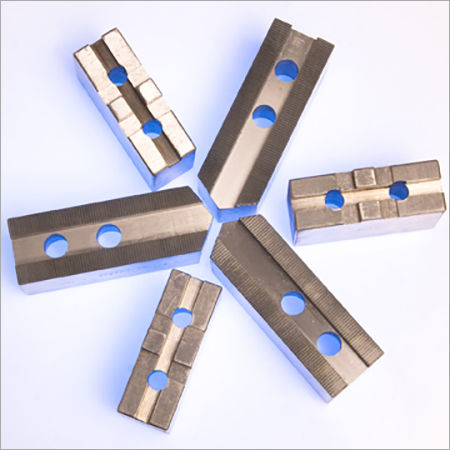

Industrial Soft Jaws

MOQ : 1 Piece

Industrial Soft Jaws Specification

- Cutting Speed

- Up to 2500 RPM

- Shape

- Rectangular, custom profile available

- Weight

- Typically 0.5 kg - 2.5 kg/piece

- Load Capacity

- Up to 2000 kg clamping force

- Coating

- Rust preventive oil

- Machine Type

- Lathe, CNC turning center, vertical and horizontal machining center

- Size

- Standard and custom sizes available

- Thread Type

- Metric fine thread

- Hardness

- 32-35 HRC (before hardening), suitable for subsequent machining

- Method

- Machinable jaws, to be soft turned to required profile

- Accuracy

- 0.015 mm as per DIN standards

- Spindle Speed

- Max 4000 RPM

- Type

- Soft jaws for power chucks and manual chucks

- Material

- High-grade alloy steel

- CNC

- Yes

- Tolerance

- 0.01 mm

- Surface

- Precision ground, smooth finish

- Use

- Workpiece clamping and holding

- Application

- Turning, milling, and machining operations

- Usage & Applications

- Ideal for gripping delicate or irregular workpieces in industrial environments

Industrial Soft Jaws Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2-7 Days

About Industrial Soft Jaws

Discover the new and latest Industrial Soft Jaws, crafted with matchless precision and ephemeral elegance for critical workholding needs. Engineered from high-grade alloy steel, these rectangular soft jaws promise unmatchable machinability and lofty performance in industrial turning, milling, and machining operations. Enhanced wear resistance ensures durability for multiple cycles, while advanced rust protection and a Blanchard ground finish safeguard integrity in harsh environments. Compatible with industry-standard chucks like Kitagawa, SMW, and Autoblok, these CNC-ready jaws are certified to ISO 9001:2015 and offer exceptional accuracy of 0.015 mmtruly unmatched for your production demands.

Advanced Industrial Soft Jaws: Application & Features

Industrial Soft Jaws are predominantly used for securely clamping and holding delicate or irregular workpieces during turning, milling, and machining. Crafted from high-grade alloy steel, they are resilient and suitable for custom profiling. The jaws deliver a smooth, precision-ground surface, exceptional machinability, and are both CNC-lathe and manual-chuck compatible. Enhanced with corrosion resistance and a robust 32-35 HRC hardness, they support high spindle speeds and maintain accurate workpiece positioning, making them indispensable in demanding manufacturing environments.

Market Value, Logistics & Pricing Advantage

With our efficient supply chain and strategic base in India, we guarantee robust supply ability and timely delivery at the lowest price. Our logistics network is optimized for both domestic and international shipments, serving markets with high-value industrial needs. The FOB Port is typically Mumbai, reflecting seamless export capability. Our competitive pricing, matched with the market value of these precision-crafted soft jaws, ensures maximum value in terms of quality, durability, and customer satisfaction across various industrial sectors.

Advanced Industrial Soft Jaws: Application & Features

Industrial Soft Jaws are predominantly used for securely clamping and holding delicate or irregular workpieces during turning, milling, and machining. Crafted from high-grade alloy steel, they are resilient and suitable for custom profiling. The jaws deliver a smooth, precision-ground surface, exceptional machinability, and are both CNC-lathe and manual-chuck compatible. Enhanced with corrosion resistance and a robust 32-35 HRC hardness, they support high spindle speeds and maintain accurate workpiece positioning, making them indispensable in demanding manufacturing environments.

Market Value, Logistics & Pricing Advantage

With our efficient supply chain and strategic base in India, we guarantee robust supply ability and timely delivery at the lowest price. Our logistics network is optimized for both domestic and international shipments, serving markets with high-value industrial needs. The FOB Port is typically Mumbai, reflecting seamless export capability. Our competitive pricing, matched with the market value of these precision-crafted soft jaws, ensures maximum value in terms of quality, durability, and customer satisfaction across various industrial sectors.

FAQs of Industrial Soft Jaws:

Q: How are Industrial Soft Jaws customized for specific applications?

A: Industrial Soft Jaws can easily be machined to a custom gripping profile, allowing them to securely hold workpieces of diverse shapes and sizes for specialized machining operations.Q: What makes the material of these jaws suitable for industrial use?

A: Made from high-grade alloy steel, these jaws offer enhanced wear resistance, corrosion protection, and a tough 32-35 HRC hardness, making them ideal for repeated use in demanding industrial conditions.Q: Where can these soft jaws be used in manufacturing?

A: These soft jaws are designed for use in CNC lathes, turning centers, vertical and horizontal machining centers, and manual chucks, fitting industry-standard systems such as Kitagawa, SMW, and Autoblok.Q: What is the process for mounting and machining these jaws?

A: The jaws are mounted using metric fine threads; after installation, they can be soft turned or machined to the required profile, achieving exceptional gripping precision for your workpiece.Q: What benefits do these jaws offer in terms of operational efficiency?

A: Their high accuracy (0.015 mm), smooth Blanchard ground finish, and ability to operate at spindle speeds up to 4000 RPM ensure efficient, repeatable, and reliable clamping, reducing setup time and increasing productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS